Auger Screw Repair

Industrial Repair & Rebuild Services To Reduce Downtime and Lower Costs

With almost 50 years of repair and rebuild experience, we have developed many of the standard processes used in the industry today. Trust our team with your production. Your Satisfaction Is Our Motivation!

Expert Auger Screw Repair Services To Enhance Efficiency and Reliability

Our specialized Auger Screw Repair service addresses critical issues in the functionality and efficiency of your industrial auger screws, which are essential components in conveying materials in various industries, including agriculture, construction, and manufacturing. We understand that wear and tear, blockage, and improper alignment can severely impact your operations, leading to downtime and decreased productivity.

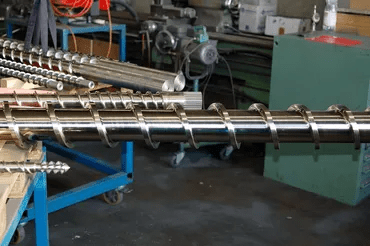

Our Auger Screw Repair service is designed to quickly and effectively restore your equipment to peak performance. We tackle common problems such as abrasion damage, flight wear, and clogging, using state-of-the-art technology and replacement parts that meet or exceed OEM standards. With our precise diagnostics and repair techniques, we ensure that your auger screws regain their optimal functionality and durability, helping to extend their lifespan and enhance your operational efficiency. Let us help you minimize downtime and maintain continuous, smooth operations with our reliable repair solutions.

We work with brands including Milacron, Kraus Maffei, Welex, Maplin, Battenfeld-Cincinnati, Sterling, Werner Pfleiderer, Davis Standard, NRM, Coperion, and many more.

Consider the cost of replacement vs. repair before making the decision to purchase new equipment. We offer a 72 month in-use warranty!

About Our Auger Screw Repair Services

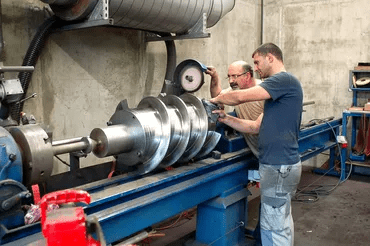

At Screw And Barrel Repair, our Auger Screw Repair process is thorough and meticulous, ensuring that every aspect of your auger screw's functionality is optimized. The process begins with a comprehensive diagnostic assessment, where we employ advanced techniques such as ultrasonic testing and metallurgical analysis to pinpoint wear patterns, structural integrity issues, and material fatigue. This initial evaluation helps us understand the extent of damage and the specific repairs needed.

Once we have identified the problem areas, our skilled technicians proceed with the disassembly of the auger screw. Each component is carefully inspected for signs of abrasion, corrosion, or distortion. We pay special attention to the helical flights, drive shaft, and hanger bearings, which are critical for the efficient operation of auger screws. Using precision tools and equipment, any damaged parts are either refurbished or replaced with high-quality, durable materials that are compatible with your specific machinery.

The reassembly phase is crucial, as it involves the precise alignment of the auger screw components. Our team uses state-of-the-art alignment technology to ensure that all parts are perfectly synchronized, which reduces the risk of future wear and tear and maximizes the efficiency of material handling. Additionally, we apply advanced welding techniques and wear-resistant coatings to enhance the durability of the auger screw, protecting it against the harsh environments it operates in.

Finally, our service includes a rigorous testing and calibration phase to ensure that the repaired auger screw performs to its highest potential. We conduct load testing and operational simulations that mimic real-world conditions. This not only confirms the functionality of the auger screw but also optimizes its performance parameters such as torque, speed, and energy efficiency. By the time we complete our repairs, your auger screw will be fully restored to its original or even better operating condition, ready to handle the demands of your industry with reliability and precision.

With nearly five decades of expertise in the field, we stand as pioneers in developing the industry's standard processes for screw rebuilding. When you choose Screw and Barrel Repair, you're not just choosing a service provider; you're partnering with a team of dedicated professionals who are passionate about delivering superior quality and unmatched reliability. Experience the difference with Screw and Barrel Repair - where precision meets perfection, and your satisfaction is our top priority.

Need Immediate Service?

We Offer Emergency Repair 24/7 - Call Us Anytime!

As an added service, we offer emergency repair services nationwide. Broken equipment? Is emergency repair needed? We are an authorized emergency service repair shop. We are willing to work overtime on your job until it is completed, giving you the fastest delivery time in the industry. Delivery time depends on the specific work to be performed. Whatever your repair needs are, no matter how big or small, we can help!

Request A Free Quote or Emergency Repair Service!

Is your equipment in need of immediate attention? When equipment is rebuilt properly, it can often be rebuilt time and time again, resulting in massive savings for your company. Call Screw And Barrel Repair for repair and rebuild services done right.

We make the repair process easy

1

Contact Us Via Phone or Send Us A Message Online

Get in touch with us effortlessly by phone or through our convenient online messaging system.

2

Free Pick-Up & Delivery Anywhere In The USA & Canada

Enjoy complimentary pick-up and delivery services spanning across the USA and Canada.

3

Top-Tier Service With Industry-Leading Turnaround Time

Experience superior service with turnaround times that set the industry standard.

Frequently Asked Questions

Please reach us at (832) 935-1692 if you cannot find an answer to your question.

Request A Free Quote or Emergency Repair Service!

Is your equipment in need of immediate attention? When a screw is rebuilt properly, without narrowing flight widths, the screw can be rebuilt time and time again, resulting in massive savings for your company. Call Screw And Barrel Repair for repair and rebuild services done right.