Extruder Gearbox Repair

Industrial Repair & Rebuild Services To Reduce Downtime and Lower Costs

With almost 50 years of repair and rebuild experience, we have developed many of the standard processes used in the industry today. Trust our team with your production. Your Satisfaction Is Our Motivation!

Expert Extruder Gearbox Repair Services: Enhancing Performance and Reliability

Our dedicated Extruder Gearbox Repair service targets critical performance issues and prolongs the operational lifespan of your extruder gearboxes, which are essential for effective plastic, rubber, and composite processing. Commonly encountered problems such as gearbox wear, oil contamination, bearing failure, and thermal instability can severely disrupt your production lines and lead to costly downtime.

At Screw And Barrel Repair, we understand that every minute of production counts. Our comprehensive gearbox refurbishment includes precision gear alignment, replacement of faulty bearings, and restoration of housing and shaft integrity. These proactive repairs not only restore your equipment to peak operational condition but also preempt potential failures, ensuring your manufacturing processes run smoothly and efficiently with minimal disruption.

We work with brands including Milacron, Kraus Maffei, Welex, Maplin, Battenfeld-Cincinnati, Sterling, Werner Pfleiderer, Davis Standard, NRM, Coperion, and many more.

Consider the cost of replacement vs. repair before making the decision to purchase new equipment. We offer a 72 month in-use warranty!

About Our Extruder Gearbox Repair Services

At Screw And Barrel Repair, our Extruder Gearbox Repair process is detailed and meticulous, ensuring every component functions optimally to reduce downtime and increase productivity. Here's a closer look at our approach:

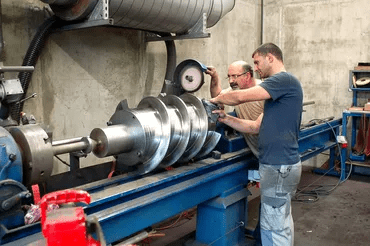

Initial Diagnosis and Disassembly: Our repair starts with a comprehensive diagnostic check using advanced vibration analysis and thermography to pinpoint mechanical issues like misalignment or excessive heat generation. Once issues are identified, our technicians meticulously disassemble your gearbox, cataloging each component to ensure flawless reassembly. This includes the removal of gears, bearings, seals, and the gearbox housing.

Component Inspection and Restoration:

Each part undergoes a thorough inspection for wear, damage, and operational integrity. We employ precision grinding for gear teeth to restore profiles, ultrasonic testing to detect cracks, and magnetic particle inspection for ferrous materials. Our restoration process may involve hard chrome plating and surface treatments to enhance wear resistance and component longevity.

Replacement and Re-engineering: In cases where components are beyond repair, we provide high-quality replacements that meet or exceed OEM specifications. For recurrent failure modes, our engineering team can re-design elements like gear geometry or bearing arrangements to enhance performance and adapt to new operational demands. This step is crucial for ensuring that the gearbox not only returns to its original state but also improves in aspects that prevent future failures.

Reassembly and Testing: The gearbox is reassembled with precision, followed by rigorous testing to ensure it meets all operational standards. Our testing includes load testing, leak testing for seals, and final adjustments to gear alignments and torque settings. This thorough testing guarantees that your extruder gearbox will operate seamlessly under full production conditions, maximizing efficiency and reliability.

Through this detailed and expert-driven process, we ensure that your extruder gearbox repair extends the equipment's life and optimizes your manufacturing efficiency. At Screw And Barrel Repair, we don’t just fix gearboxes; we enhance and fortify them against future challenges.

With nearly five decades of expertise in the field, we stand as pioneers in developing the industry's standard processes for screw rebuilding. When you choose Screw and Barrel Repair, you're not just choosing a service provider; you're partnering with a team of dedicated professionals who are passionate about delivering superior quality and unmatched reliability. Experience the difference with Screw and Barrel Repair - where precision meets perfection, and your satisfaction is our top priority.

Need Immediate Service?

We Offer Emergency Repair 24/7 - Call Us Anytime!

As an added service, we offer emergency repair services nationwide. Broken equipment? Is emergency repair needed? We are an authorized emergency service repair shop. We are willing to work overtime on your job until it is completed, giving you the fastest delivery time in the industry. Delivery time depends on the specific work to be performed. Whatever your repair needs are, no matter how big or small, we can help!

Request A Free Quote or Emergency Repair Service!

Is your equipment in need of immediate attention? When equipment is rebuilt properly, it can often be rebuilt time and time again, resulting in massive savings for your company. Call Screw And Barrel Repair for repair and rebuild services done right.

Call Us For Extruder Repair and Rebuild Done Right!

Our Extensive Extruder Repair Process

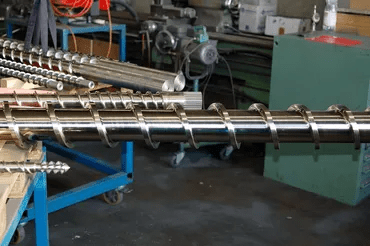

- Completely clean and strip all chrome or nitride coatings for preparation, inspection, and measurements to evaluate the extent of repair needed for your extruder.

- Measure the outer diameter (OD) of each flight to assess wear and inspect the root diameter.

- Precision OD grind to remove all existing hard facing, preparing a new layer of material for your extruder screw repair.

- Restore the root diameter to perfection, ensuring no pits, zits, or pinholes. We apply an 8RMS finish to the root at this point.

- Apply coatings such as Hastalloy, C56, or other hard facing materials (5 options available) to the OD of all flights, building beyond the original size.

- Precision side grinding to remove excess hard facing from flights, essentially trimming the added material from your extruder screw flights.

- Utilize dye penetrant testing to identify any cracks, pinholes, etc., and perform necessary repairs.

- Polish the entire screw to a 6RMS mirror finish in preparation for plating or nitriding.

- Apply hard chrome plating, electroless nickel plating, or nitriding across the entire screw and buff to a 4/5RMS mirror finish. Comply with Military Spec QQC-320B & Military Spec Mil-C-26074B Class A Grade 1. For the most durable exterior coating in harsh environments, we recommend CEB coating: Chrome over Electroless Nickel, baked at 475 degrees for 3 to 5 hours. A 2-year warranty covers all CEB coatings against pitting, chipping, burning, etc.

- Precision OD grind the flights to your specified size.

- Inspect all sizes, straightness, root diameter, and prepare for the final buffing and polishing.

- Complete the final inspection of all sizes and tolerances, and perform final buffing to a mirror finish. Prepare for shipping with crating, foam insulation, and metal banding to your dock.

The final product is an extruder screw repair that surpasses OEM specifications/tolerances and performs like new. Fully guaranteed for one year. Delivery time is half that of our competitors. We surpass OEM specifications for polish finish, hard facing strength, straightness, TIR, plating thickness, etc. Our extruder repairs outperform new extruders, offering better warranties and lower prices.

We rebuild your extruder either to the exact original size or make it oversized to match your current barrel. If built to size, the repair makes your extruder fully interchangeable with any barrel. If built to a specific size, it remains dedicated to that barrel until the next rebuild. If your extrusion barrel is honed oversized to 100% cleanup, we can rebuild your extruder to match. This option saves significant costs over a barrel relining, which is expensive and time-consuming. However, this means the extruder and barrel are fixed to each other until the next repair cycle.

Types of Injection Screws & Other Equipment We Specialize in Rebuilding

- Gearbox repair

- Electric motor repair

- Platens and tie bar repair

- Toggle assembly repair

- Injection screw tip repair

- Single extrusion screw repair

- Conical twin screw repair

- Parallel twin screw repair

- Plastic and rubber injection molding feed screw and barrel repair

- Plastic and rubber extrusion screws and barrels repair

- Barrel or feed throat relining and repair

- Sheet die repair

- Blown film die repair

- Converting equipment repair

- Melt pump repair

- Calender roll grinding and repair

- Roll grinder and repair

Plastic Manufacturing

- Extrusion

- Rotational Molding

- Blown Film Extrusion

- Blow Molding

- Vacuum Forming

- Polymer Casting

- Thermo Molding

- Injection Molding

Rubber Manufacturing

- Coating

- Transfer Molding

- Casting

- Tire Manufacturing

- Rubber Extrusion

- Injection Molding

- Rubber Calendering

- Compression Molding

We make the repair process easy

1

Contact Us Via Phone or Send Us A Message Online

Get in touch with us effortlessly by phone or through our convenient online messaging system.

2

Free Pick-Up & Delivery Anywhere In The USA & Canada

Enjoy complimentary pick-up and delivery services spanning across the USA and Canada.

3

Top-Tier Service With Industry-Leading Turnaround Time

Experience superior service with turnaround times that set the industry standard.

Frequently Asked Questions

Please reach us at (832) 935-1692 if you cannot find an answer to your question.

Request A Free Quote or Emergency Repair Service!

Is your equipment in need of immediate attention? When a screw is rebuilt properly, without narrowing flight widths, the screw can be rebuilt time and time again, resulting in massive savings for your company. Call Screw And Barrel Repair for repair and rebuild services done right.